ITECH

Spring 2019

University of Stuttgart

As part of the ITECH Master Studio, I joined the class to produce a series of 5 bio-fiber column-thruss element using bio-fiber and bio-resion fully. The workflow of the research was compartmented into different groups. Here represented only Material, Physical Model and Prototype.

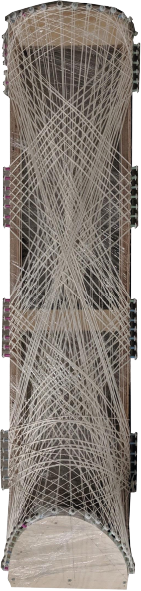

In parallel with the global design of the pavilion, the component form and weaving syntax are started to be studied to best carry out the load. Various models are tried for different thread juxtapositions. Syntax studies of Roof Components include (in order) ‘circular condition for Roof-Mullion connection’, ‘sharper circular edge condition for Roof-Mullion connection’, ‘sharper edge condition for Roof-Mullion connection’.

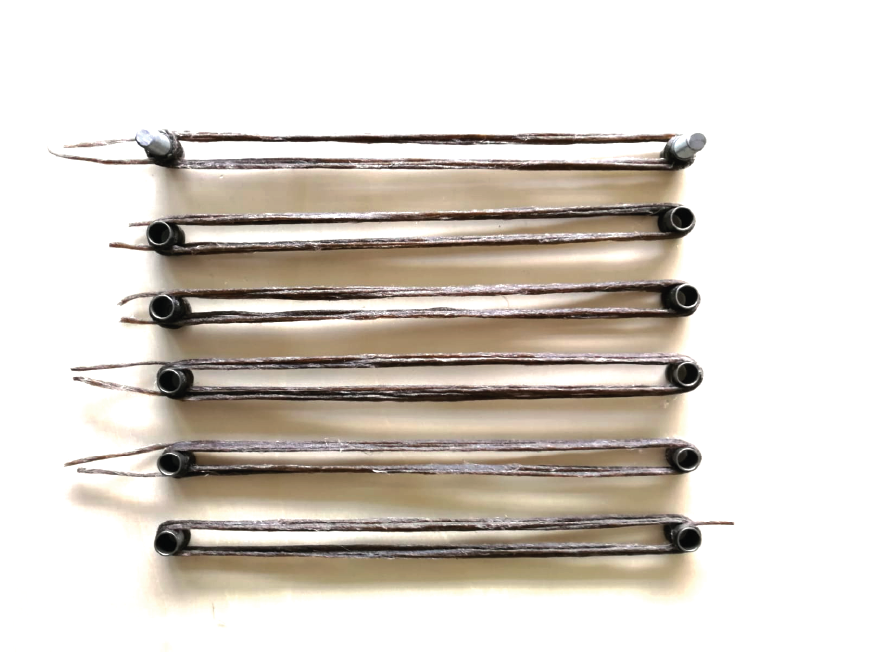

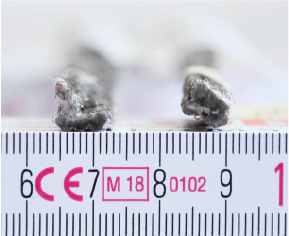

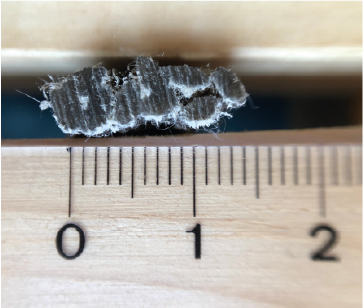

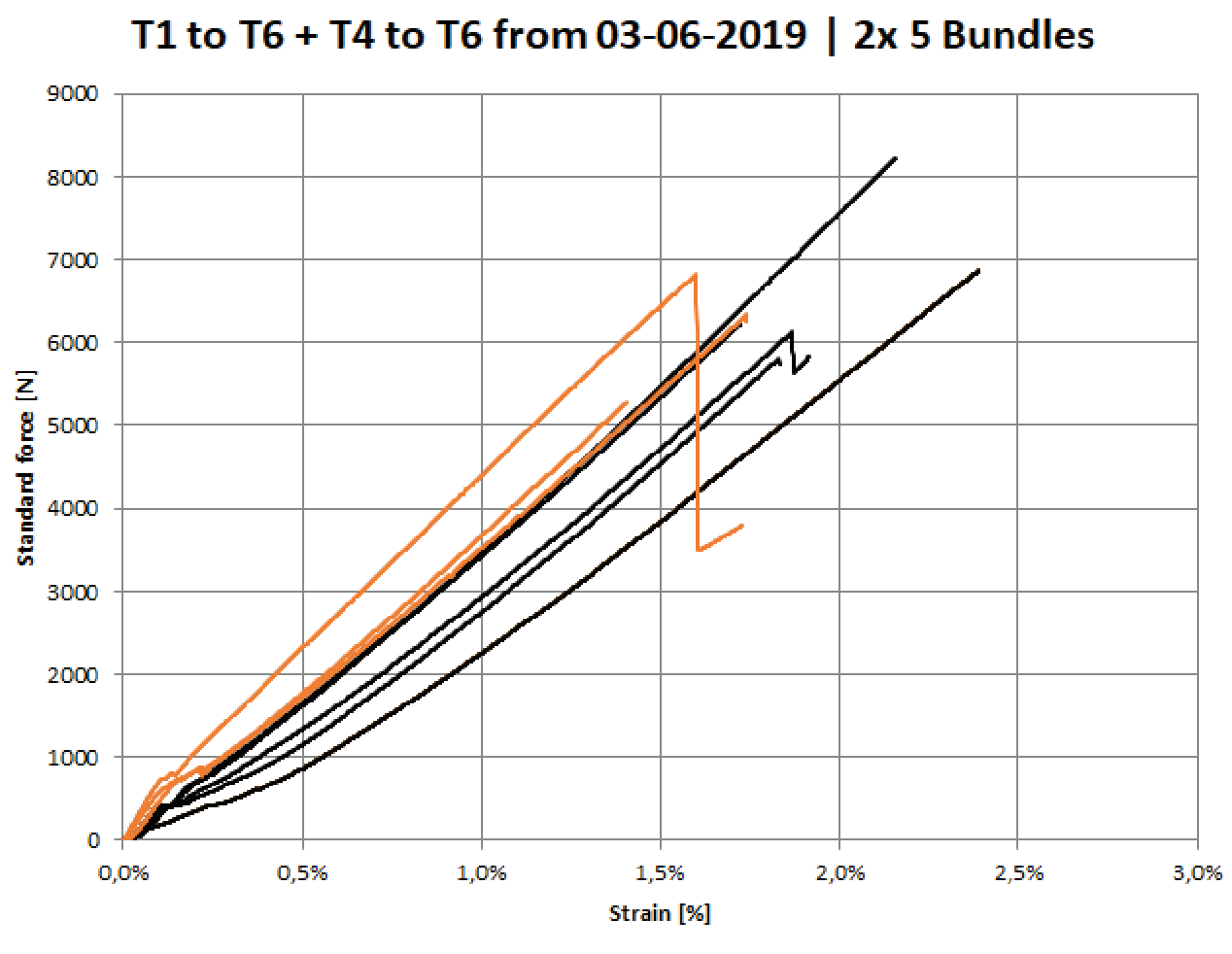

Due to the lack of any referance data on full bio-fiber and bio-resin structures, material tests are conducted to find the optimum section of bundles as well as the resin amount to be applied.

Due to the lack of any referance data on full bio-fiber and bio-resin structures, material tests are conducted to find the optimum section of bundles as well as the resin amount to be applied. Different tension bundles are prepared each composed of with a different amount of bio-fiber and bio-resion.

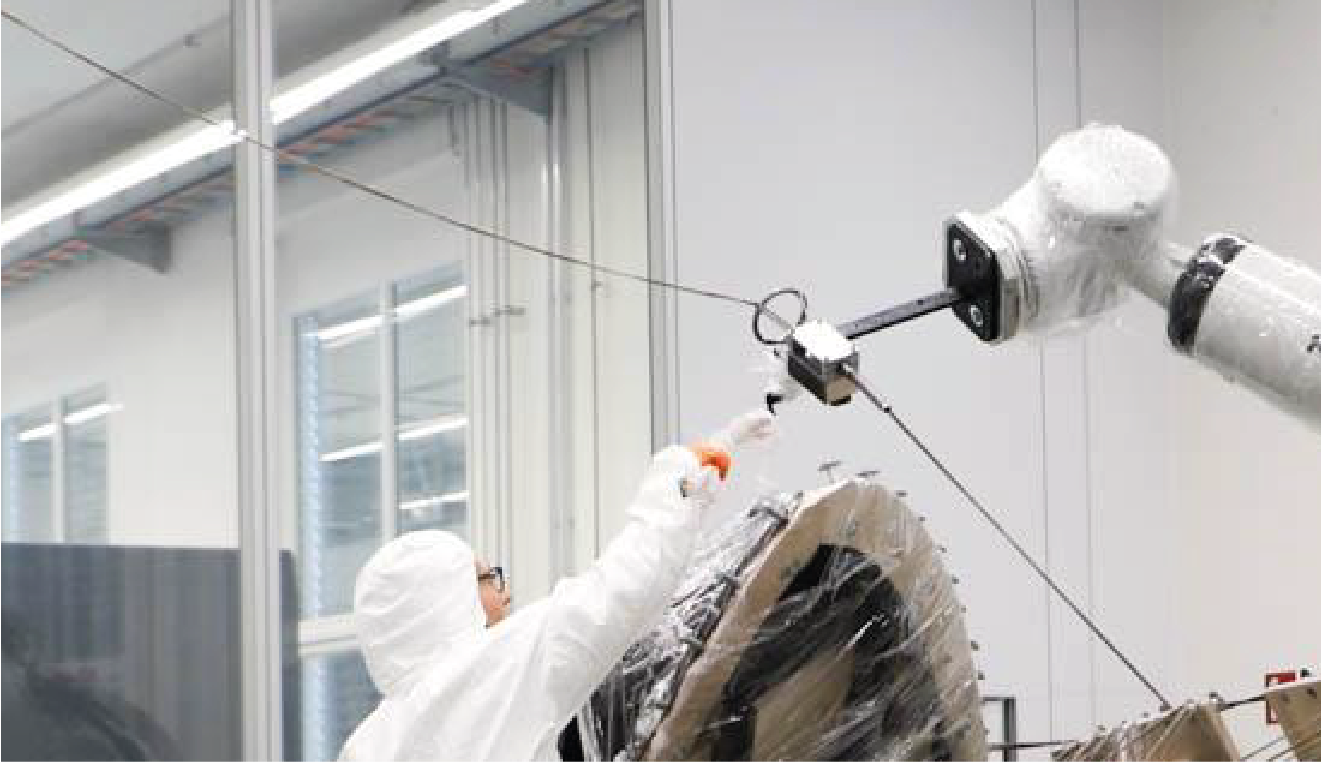

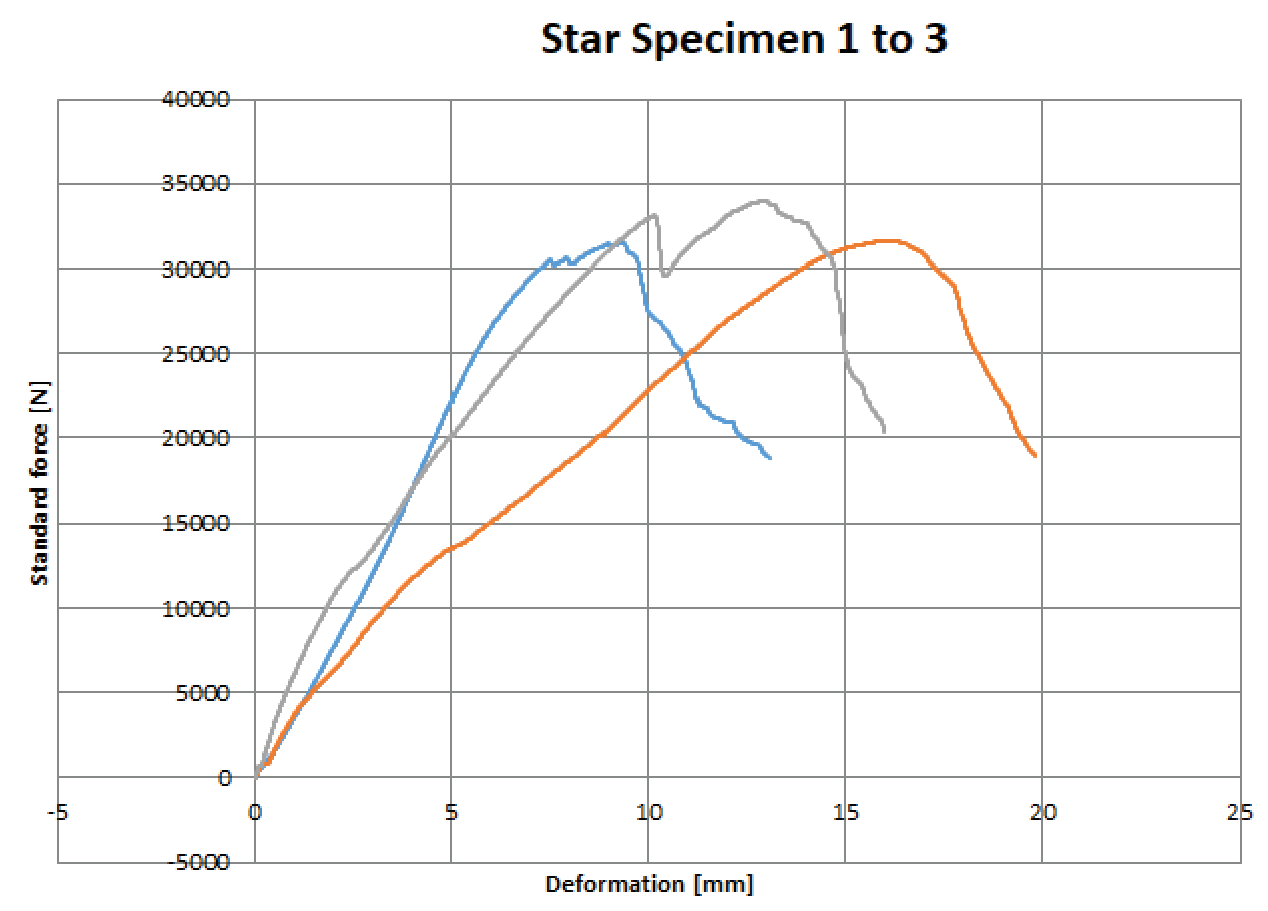

Star-shaped bundles are weaved with Kuka Robot to test the compression limits. Different composition are produced to measure the cohesion and bundle interaction, as well as to assess buckling behaviour in comparison to carbon fiber.

After the tension tests, the results were compared with laminate’s. Modules of Elasticity is 20% of laminates, the tensile strength is found out to be 25% laminate’s.

After the compression test, the results were compared with carbon-fiber’s to predict the possible weakness points in the design. Maximum force that could be carried by bio-fiber was 31kN in comparison to carbon’s 80kN.